Understanding Your Car Accident Repair Timeline: How Long Does Auto Body Repair Take?

When drivers ask, “how long does auto body repair take?” they’re really asking for a clear timeline — from the first inspection to the final quality check. That timeline covers visible fixes, hidden structural work, parts sourcing, paint and curing, safety-system calibrations, and final sign-off. Every stage affects the total repair time. This guide walks through typical collisionrepair durations, the key steps you’ll experience, what speeds repairs up or slows them down, and how insurance approvals fit into the schedule. You’ll also find realistic comparisons for minor versus major repairs and practical steps to track progress from intake to delivery. Our goal is to give you honest averages and useful actions so your car moves through the shop as smoothly as possible.

Prime Time CollisionCenter is a Glendale-based shop that helps customers move through the repair timeline confidently. We focus on OEM-quality repairs, I-CAR Platinum–certified technicians, and a lifetime warranty on our work. Our service model — free estimates, 24/7 towing support, and coordination with all major insurers — is designed to cut down the administrative delays that often lengthen repair time. Mentioning our shop up front shows how a repair provider can influence timing, but the main purpose here is to educate you about the process and expected durations. Ahead you’ll find the stages, the main time drivers, how insurance affects timing, why certification matters, typical timelines for different levels of damage, and tips for tracking your repair’s progress.

What Are the Key Stages in the Car Accident Repair Process?

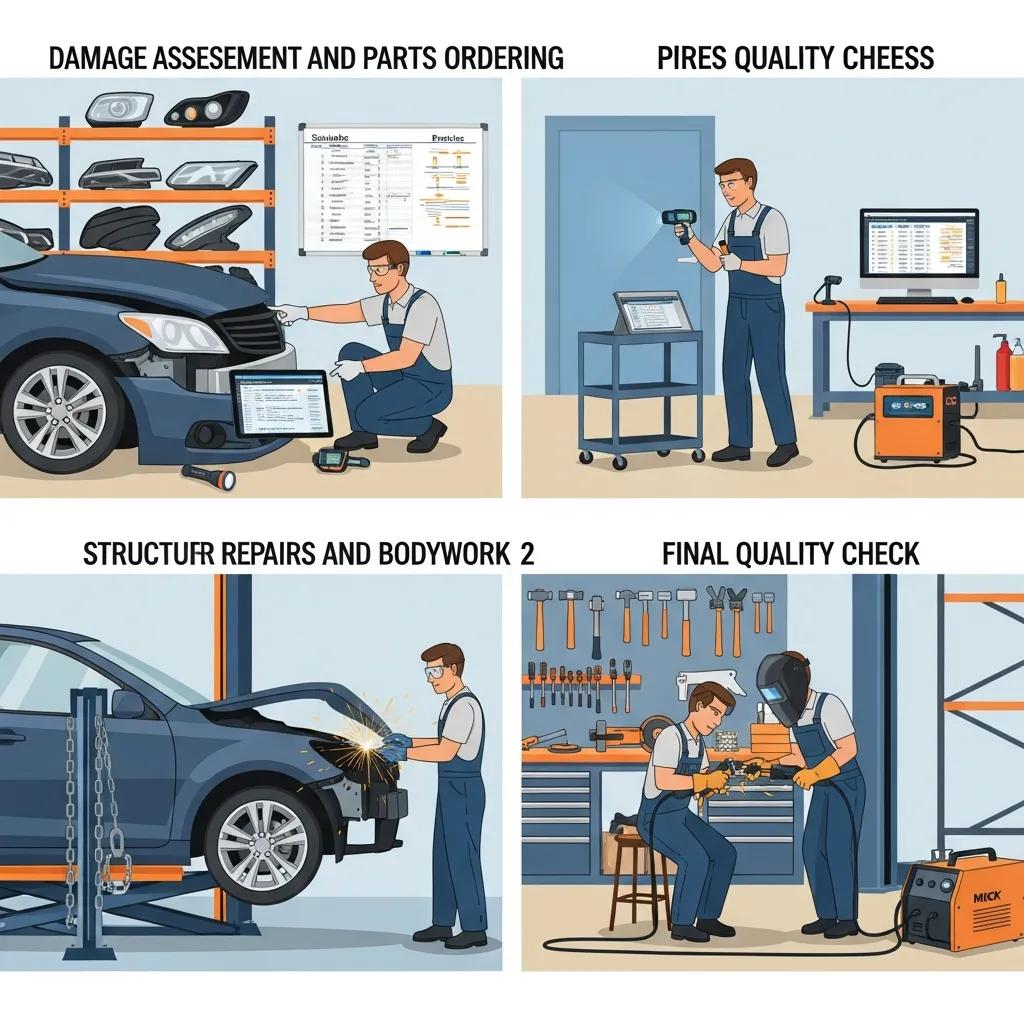

A collisionrepair timeline is made up of sequential stages, and each one adds measurable time to the overall job. The major steps are intake and estimate, insurance approval, parts ordering, disassembly and discovery of hidden damage, structural or panel repair, paint and refinishing, reassembly and ADAS calibration, and final quality control. Each step depends on the one before it — for example, we can’t start painting until alignment and panel fit are confirmed — so timelines are realistic estimates, not guarantees. Knowing these stages helps you ask the right progress questions and understand which dates are likely to move. Below is a simple list of the core stages you’ll see when tracking a collisionrepair.

- Initial assessment and estimate: A thorough inspection documenting visible and suspected hidden damage.

- Insurance approval and authorization: Adjuster review and sign-off for repairs and parts.

- Parts sourcing and ordering: OEM or approved aftermarket parts are ordered based on availability.

- Disassembly, structural repair, paint, and reassembly: Sequential technical work that ends with quality checks.

This stage framework helps you estimate total time and highlights where good communication and shop advocacy can reduce delays. Next we break those stages into typical time windows so you can get a quick read on what to expect.

Below is a stage-by-stage reference table that summarizes common tasks and realistic duration ranges for each phase.

| Stage | Typical Tasks | Typical Duration (estimate) |

|---|---|---|

| Initial assessment & estimate | Visual inspection, diagnostic scans, ADAS checks, photo documentation | 1–2 days |

| Insurance review & authorization | Adjuster review, approvals, supplemental estimate handling | 1–7 days (varies) |

| Parts ordering & delivery | OEM parts sourcing, aftermarket alternates, lead-time confirmation | 2 days–3+ weeks |

| Disassembly & structural repair | Reveal hidden damage, frame alignment, welding, panel replacement | 1–7 days |

| Paint & refinishing | Prep, color match, paint application, curing | 1–5 days |

| Reassembly & ADAS calibration | Reinstall parts, calibrate sensors, system verification | 1–3 days |

| Quality control & delivery | Road test, inspection, warranty documentation | 1–2 days |

How Is the Initial Assessment and Damage Estimate Conducted?

The initial assessment sets the scope of the repair timeline. Technicians document visible damage, take photos, and run diagnostic scans to check ADAS and other electronic systems. A good estimate includes parts, labor hours, and likely supplemental work — and it sets expectations with both you and the insurer. If the damage suggests hidden issues, we may recommend controlled disassembly to confirm scope. That adds time up front but prevents later surprises and repeat disassembly. A careful assessment usually saves time overall by avoiding rework and helps speed insurance approvals and parts ordering.

What Happens During Disassembly, Structural Repair, and Paint Phases?

Disassembly uncovers hidden damage that wasn’t obvious at first, which is why this phase can change the timeline. Technicians remove panels and components to inspect structural members, fasteners, and mounting points. If frame or subsystem damage is found, repairs require precision tooling and alignment checks — methodical work that takes time. Structural and body repairs follow manufacturer procedures and jigs to restore alignment within OEM tolerances; this protects safety performance and warranties. Paint only begins after structural integrity and panel fit are confirmed. Paint work requires careful prep, color matching, application, and curing — steps that can’t be rushed without risking defects. Proper sequencing between disassembly, structure, and paint reduces the chance of rework and delivers a durable repair.

Which Factors Affect the Duration of Your CollisionRepair?

Several internal and external factors determine how long a repair takes. Key influences are the severity of the damage and vehicle complexity, parts availability and supplier lead times, the shop’s current workload and technician capacity, and the speed of insurance approvals and supplemental authorizations. These factors often interact — for example, a complex vehicle needing OEM parts and ADAS calibration will take longer if parts are delayed or the shop is busy. Knowing these drivers lets you prioritize actions that reduce delays, like authorizing OEM parts early or asking the shop to submit full documentation promptly. The short list below shows the most common time drivers to watch for.

- Damage severity and structural involvement: More extensive damage means more labor and specialized work.

- Parts availability and supply-chain delays: Waiting on parts can dominate the timeline.

- Shop workload and technician capacity: Backlogs affect scheduling and completion dates.

- Insurance approval and supplemental negotiation: Work can pause until authorizations arrive.

Below is a simple table linking each factor to its time impact and how a reputable shop can help reduce delays.

| Factor | How It Impacts Time | How Prime Time Mitigates (if applicable) |

|---|---|---|

| Damage severity & vehicle complexity | More hours for diagnosis, frame work, and calibrations | We follow I‑CAR procedures and use experienced technicians to streamline repairs |

| Parts availability | Waiting for OEM parts can add days to weeks | Proactive ordering and alternative sourcing when appropriate |

| Shop workload | High backlog delays start and completion dates | We prioritize clear communication and transparent scheduling |

| Insurance approvals | Hold-ups for authorization and supplements | We liaise with insurers and submit full documentation quickly |

This breakdown shows the common causes of delays and how shops that emphasize OEM quality and claims coordination can help keep your repair on schedule. Next, we look at how damage severity and vehicle type change expected durations and why hidden damage matters.

How Do Damage Severity and Vehicle Type Influence Repair Time?

Severity of damage is the main driver of repair time: cosmetic fixes take far less time than structural restoration. Vehicles with advanced systems or complex construction add specialized tasks and testing. For example, a bumper scuff typically needs paint and blending, while frame alignment, multiple panel replacements, or EV-specific components require more hours and specialist technicians. Luxury, European, and electric vehicles often need OEM parts or factory procedures that extend lead times and labor. Hidden damage found during disassembly can add unexpected days because additional parts must be ordered and insurers may need to approve supplements. Expect a range of time, not a single fixed date.

What Role Do Parts Availability and Shop Workload Play in Delays?

Parts lead times and shop backlog are among the most common, uncontrollable delays. OEM parts usually need longer lead times but ensure correct fit and safety conformity; aftermarket options can be faster but may affect warranty or fit. Shops that manage inventory well, have strong supplier relationships, and proactively track parts can shorten waiting windows. Conversely, a busy shop may delay start dates regardless of part status. At Prime Time Collision, we coordinate parts orders early, communicate delivery estimates, and work with insurers on parts approvals to reduce uncertainty and keep repair time close to the initial estimate.

How Does the Insurance Claim Process Impact Your Car Repair Timeline?

The insurance claim process touches repair schedules at several points, and approval timing often determines when work can start or resume. Typical insurer steps include filing the claim with documentation, an adjuster review and inspection, estimate reconciliation or supplements, and final authorization to proceed. Delays usually happen when supplemental damage is found after disassembly or when parts or labor items require insurer approval — each hold can add days or weeks. A shop that submits clear estimates, photos, and diagnostic data up front can shorten insurer review and reduce back-and-forth. Understanding the insurer workflow and expected time ranges helps you anticipate bottlenecks and the likely overall repair timeframe.

- Filing and documentation: Provide photos, police reports, and vehicle details promptly.

- Adjuster inspection and estimate review: The insurer or independent adjuster reviews the shop estimate.

- Authorization and supplements: The insurer issues approval; supplements may be needed after disassembly.

- Final payment and repaircommencement: Authorization triggers parts ordering and scheduling.

Each of these steps is a potential pause point in the timeline, and being prepared with complete documentation helps speed the process. Below we explain how a shop like Prime Time Collision supports customers through the claim process.

What Steps Are Involved in Insurance Approval for Repairs?

Insurance approval usually follows a predictable sequence that affects how quickly work moves. After you file, documentation and photo evidence create an initial estimate; an adjuster may inspect in person or accept the shop’s estimate. If disassembly reveals additional damage, the shop submits a supplemental estimate and waits for reevaluation. Once authorization arrives, parts are ordered and the job is scheduled — but if the insurer delays or disputes items, work may pause. Providing complete documentation and responding promptly to insurer requests reduces approval cycles and shortens total repair time.

How Does Prime Time Collision Center Assist with Insurance Claims?

At Prime Time Collision Center we act as your advocate during insurer interactions. We prepare detailed documentation, communicate directly with adjusters, and submit clear photos and diagnostic reports to minimize review time. We work with all major insurance companies, explain rental coverage and options, and proactively request supplements when hidden damage appears. Our free estimates and transparent paperwork are designed to anticipate common questions and present a complete repair scope from the start. That approach helps avoid unnecessary pauses and sets clearer expectations for parts orders and scheduling.

Why Are OEM Certified Repairs Important for Your Vehicle’s Safety and Warranty?

OEM-certified or factory-quality repairs matter because they help preserve your vehicle’s original safety performance, protect warranty considerations, and support resale value. OEM parts and certified technicians follow manufacturer procedures that keep crashworthiness and component fit within factory tolerances — very important for vehicles with integrated systems like ADAS. Certified repairs also reduce fit-and-finish issues that can lead to rework and timeline extensions. If you care about long-term safety and warranty protection, OEM-quality repairs align work with the vehicle’s original engineering and lower the chance of future problems.

- Safety retention: OEM parts and factory procedures preserve crash structures and sensor performance.

- Warranty protection: Certified repairs are more likely to maintain manufacturer warranty terms.

- Resale and fit-and-finish: Factory-quality repairs improve long-term value and reduce rework risk.

Those benefits explain why many owners choose OEM-certified repairs even when parts lead times may be longer. The next section summarizes technician and parts advantages in more detail.

What Are the Benefits of OEM Parts and Certified Technicians?

OEM parts fit precisely and match the original materials and performance specs, which helps preserve crash energy management and component interfaces. Certified technicians trained to factory procedures follow specific steps for disassembly, torque settings, and calibration, reducing errors and rework that would extend the timeline. Proper ADAS calibration by trained technicians ensures driver assistance features work as intended after repairs — a safety-critical outcome of OEM-quality work. Together, these practices protect vehicle integrity and often prevent future failures that would require more repair time later.

How Does Prime Time Collision Center Ensure Factory-Quality Repairs?

We deliver factory-quality repairs through I‑CAR Platinum–certified technicians, strict adherence to OEM procedures, and documented quality-control checkpoints that verify fit, finish, and system calibrations. Our lifetime warranty on repairs and focus on factory standards hold our team accountable for both workmanship and parts selection. Our technicians are trained for ADAS calibrations and system-level checks required after structural or sensor-area work. We communicate clearly about OEM choices and calibration needs so you understand why certain steps take time and why they improve safety and reduce callbacks. By pairing certified staff with process-driven QC, we align repairs with manufacturer expectations while keeping you informed about how those steps affect the timeline.

What Is the Typical Timeline for Minor Versus Major Car Accident Repairs?

Repair timelines vary greatly between minor cosmetic work and major structural repairs. Minor repairs — bumper scuffs, small dents, or single-panel paint — often finish within a few days when parts are in stock and the shop isn’t backed up. Major repairs involving frame alignment, multiple panel replacements, ADAS recalibration, or EV components commonly take multiple weeks because of ordered parts, staged authorizations, and sequential technical steps. The comparison table below shows typical ranges and the most common delay causes so you can identify which bracket your repair is likely to fall into.

| Repair Type | Example Damage | Typical Time Range | Common Delay Causes |

|---|---|---|---|

| Minor collision repairs | Bumper scuff, small dent, single-panel paint | 1–5 days | Parts ordering, shop schedule |

| Moderate repairs | Multiple panel replacement, localized structural repair | 5–14 days | Parts lead time, supplemental approvals |

| Major collision repairs | Frame damage, complex ADAS recalibration, EV systems | 2–6+ weeks | Parts sourcing, insurer supplements, calibrations |

That comparison shows why the question “how long does it take to fix a car after an accident” has a range instead of a single answer. Knowing which category your vehicle fits helps you plan transportation while repairs are underway. The following sections break down minor and major repair timelines in more detail.

How Long Do Minor Repairs Usually Take?

Minor collision repairs often take anywhere from the same day up to about five days, depending on parts and shop scheduling. These jobs typically involve limited disassembly and straightforward paint work. If parts and paint materials are on hand and the shop’s workload is light, some cosmetic repairs finish in 24–48 hours. But even minor jobs can expand if hidden damage turns up during disassembly. Confirm with your repairer about expected pickup dates and whether OEM parts or ADAS calibration are involved, since sensor-area work can convert a minor job into a moderate one.

What Is the Expected Duration for Major Collision Repairs?

Major collisions that require frame straightening, multiple panel replacements, or ADAS/EV component work usually take several weeks — commonly two to six weeks or longer when parts lead times and insurer supplements are included. Structural repairs need precision measurements and staged procedures that can’t be rushed without risking safety. ADAS calibration may require specialized equipment or factory procedures that add time. Parts for luxury or imported models can have extended lead times outside the shop’s control. For major repairs, frequent status updates and proactive parts ordering are essential to keep the timeline as short as possible.

How Can You Track and Manage Your Car Repair Progress Effectively?

To track repair progress, know the milestone stages to expect, ask focused questions, and confirm a single point of contact at the shop for consistent updates. Common communication milestones are estimate completion, insurance authorization, parts ordered, paint start, reassembly, ADAS calibration, and final inspection. Request photo updates at key stages or ask for digital status notifications so you don’t need daily in-person visits. Having one primary contact reduces confusion when multiple technicians are involved. These checkpoints also make it easier to plan for rental coverage, alternate transportation, or adjustments if parts or authorizations delay the timeline.

- Estimate ready: Confirms scope and expected duration.

- Parts ordered: Signals when supply-chain variables become the schedule driver.

- Paint start and reassembly: Visible progress that usually precedes final QC.

- Final inspection and delivery: When the car is prepared for pickup and warranty paperwork is provided.

Using these milestones gives you a reliable way to check progress and anticipate next steps. The next section describes the type of communication you can expect from a proactive shop like Prime Time Collision.

What Communication Can You Expect from Prime Time Collision Center?

We provide regular milestone updates — estimate ready, parts order confirmation, paint schedule, and final inspection results — so you always know where your car is in the process. We assign a single point of contact to answer questions about authorizations, rental arrangements, and pickup dates. That keeps communication clear and prevents mixed messages that can slow a job. You’ll get transparent explanations about delays, including parts lead times or insurer holds, and photographic documentation at critical stages to verify progress. Clear, scheduled updates reduce surprises and give everyone a shared timeline while repairs are in progress.

How Do Quality Control and Final Inspections Affect Completion Time?

Quality control and final inspections intentionally add time at the end of the repair timeline to make sure safety, fit, and finish meet manufacturer standards and to avoid rework that would add even more time. QC includes visual fit-and-finish checks, road tests, system verifications, and ADAS calibration confirmations — these steps can take additional hours or a day after reassembly. While they might feel like delays, skipping or rushing QC increases the risk of problems that require later corrective work and more downtime. Accepting this final inspection window helps ensure your repair is durable and your vehicle is returned safe and ready to drive.

- Verify completed items: QC confirms all repair tasks are finished correctly.

- Test systems in real conditions: Road tests and system checks ensure performance.

- Document and warranty the repair: Final paperwork and warranty documentation complete the process.

These QC steps close the repair loop and protect you from future issues that could otherwise require additional shop time or insurer interaction.

Frequently Asked Questions

What should I do if my car repair takes longer than expected?

If your repair is taking longer than expected, contact your shop and ask for a clear status update. Request specifics — is the delay due to parts, insurer approval, or shop scheduling? Ask for an estimated completion date and whether they can provide photos or a timeline for the next milestone. If you need transportation, discuss rental options or alternatives while the work continues. Open communication usually clarifies the situation and helps identify options.

Can I choose aftermarket parts for my car repair?

Yes — aftermarket parts are often an option. They can be less expensive and sometimes arrive faster than OEM parts. But using non‑OEM parts can affect warranty terms, fit, and long-term value. Talk it over with your repair advisor and check with your insurance company before deciding so you understand the trade-offs.

How can I expedite the insurance claim process for my car repair?

To speed an insurance claim, submit complete documentation early: clear photos of the damage, a police report (if applicable), and vehicle details. Stay in touch with your adjuster and the repair shop so everyone has the same information. Choosing a shop experienced with your insurer can help — they often know the documentation the insurer wants and can reduce back‑and‑forth.

What happens if hidden damage is discovered during the repair?

If hidden damage appears during disassembly, the shop will notify your insurer and submit a supplemental estimate for the extra work. That can extend the timeline while the insurer reviews and approves the supplement. A shop that communicates quickly and provides clear photos and diagnostics can help speed that approval and minimize added delays.

Are there any warranties on the repairs done to my vehicle?

Reputable shops typically offer warranties on parts and labor. At Prime Time Collision Center we back our work with a lifetime warranty on completed repairs, so if anything related to the repair fails, we’ll address it. Always confirm warranty details before authorizing work so you know what’s covered.

How can I prepare my vehicle for the repair process?

Before bringing your vehicle in, remove personal items and give the car a quick clean. If your vehicle has ADAS or advanced systems, tell the shop so they can plan for required calibrations. Bring insurance information, any relevant repair records, and have contact details ready. Being organized helps the shop work faster on intake and keeps the process moving.

What should I expect during the final inspection of my vehicle?

During final inspection we perform a thorough quality-control check to ensure repairs meet manufacturer standards. That includes visual inspections, road tests, and system verifications — especially for ADAS components. We’ll document the work, provide warranty information, and give you a detailed report of what was completed for your records.

Conclusion

Understanding the repair timeline helps you set realistic expectations and keep your repair on track. By knowing the key stages, common delay drivers, and how insurance fits in, you can make smarter decisions and communicate more effectively with your shop. For a smoother experience, consider a trusted provider like Prime Time Collision Center — we focus on quality, clear communication, and getting you back on the road safely. Stay proactive about updates and milestones to help minimize delays and ensure timely repairs.