How Blind Spot Monitoring Systems Keep You Safer: Benefits, Repair, and Calibration

Blind spot monitoring (BSM) uses sensors and software to spot vehicles in adjacent lanes and warn drivers before risky lane changes. As part of a vehicle’s ADAS (Advanced Driver Assistance Systems), BSM combines radar, ultrasonic and camera inputs to interpret nearby traffic and give timely visual, audible or haptic alerts. For the system to work reliably, sensors must be intact and mounted correctly, wiring must be sound, and the software must be calibrated to factory references—things that can be affected even by minor impacts or collision repairs. Below we explain how BSM works, the safety gains it provides, what commonly goes wrong after an accident, and best practices for repair, sensor replacement and ADAS calibration so systems perform like they did from the factory. You’ll find sensor comparisons, simple troubleshooting steps you can try, clear guidance on when to call a pro, and an overview of OEM-certified repair and calibration workflows. We also outline how a local repair shop helps with insurance and customer confidence during BSM repairs.

What Are Blind Spot Monitoring Systems and How Do They Work?

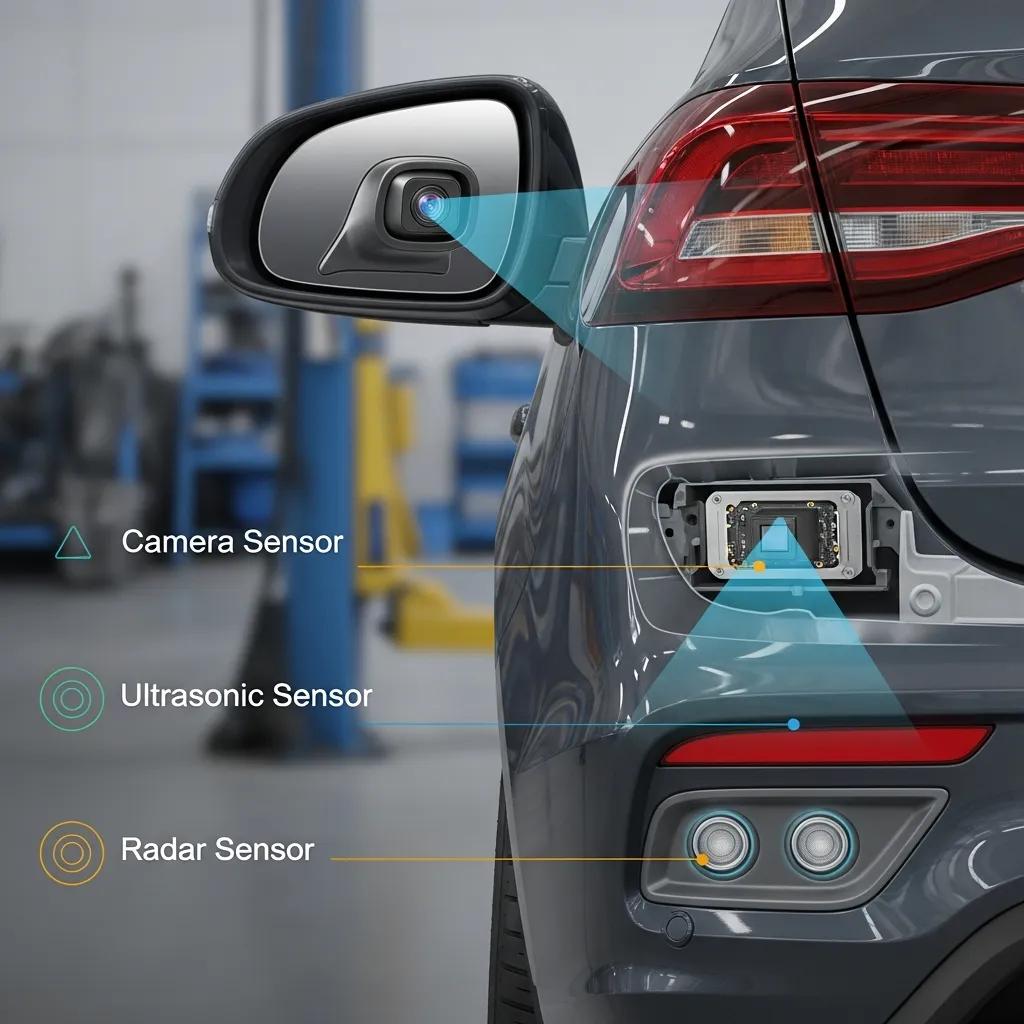

Blind spot monitoring systems use dedicated sensors and a control module to detect and classify objects in neighboring lanes and then alert the driver to help prevent unsafe lane changes. Sensors continuously sweep the area around the vehicle to measure relative distance and speed. The control module filters and fuses those inputs, and the human–machine interface delivers prioritized feedback—mirror LEDs, chimes, or steering-wheel pulses—so drivers get clear, actionable warnings. Because BSM is an ADAS feature, it’s often linked with cross-traffic alert and lane-change assist to improve awareness in multiple driving situations. Knowing how radar, ultrasonic and camera systems differ makes it easier to understand why some problems need part replacement and calibration rather than just a reset.

Different sensor types bring complementary strengths and trade-offs to blind spot detection:

| Sensor Type | Typical Mounting Location | Strengths | Typical Failure Modes |

|---|---|---|---|

| Radar sensor | Rear corners, behind the bumper fascia | Long-range distance and speed detection; works in low light and most weather | Physical damage, misalignment, water intrusion |

| Ultrasonic sensor | Lower bumper areas for short-range sensing | Accurate at close range for parking and low-speed proximity | Debris buildup, sensor drift, connector faults |

| Camera sensor | Near side mirrors or rear pillars | Visual context and object classification (helps distinguish motorcycles, bikes) | Lens obscuration, miscalibration, software errors |

What Types of Sensors Are Used in Blind Spot Monitoring Systems?

Most blind spot systems rely on a mix of radar, ultrasonic and camera sensors, each tuned to specific ranges and conditions. Radar delivers reliable distance and velocity data over longer distances and performs well in poor lighting and most weather. Ultrasonic sensors cover very short ranges—useful for parking and low-speed maneuvers. Cameras give visual detail that helps classify objects, but they need clean lenses and precise alignment. Understanding each sensor’s strengths and failure modes helps drivers and technicians troubleshoot and decide when replacement or calibration is needed.

How Do Blind Spot Monitors Detect Vehicles in Blind Spots?

BSM systems sample sensor outputs, run object-detection algorithms and fuse results from multiple sensors to determine whether a vehicle is in the blind spot and where it’s headed. Sensor fusion—pairing radar distance/velocity data with camera verification—reduces false positives from roadside objects and transient reflections. The system sets detection thresholds to balance sensitivity with false-alert avoidance; when an object meets the configured criteria, the system delivers a visual cue (for example, a mirror LED), an audible warning or a haptic nudge. This layered workflow—sensing, classification, fusion and prioritized alerting—produces timely warnings that lower lane-change risk.

What Are the Key Benefits of Blind Spot Monitoring Systems for Driver Safety?

Blind spot monitoring lowers driver workload and improves split-second decision-making by keeping continuous watch of adjacent lanes, which directly reduces the chance of lane-change collisions. Studies and safety analyses show BSM, when included in ADAS suites, measurably cuts lane-change crashes and related injuries: alerts prompt drivers to pause or abandon risky maneuvers. For everyday drivers the main benefits are fewer near-misses, less severe collisions when they do happen, and greater confidence in heavy traffic or low-visibility conditions. These gains apply to personal vehicles and fleet cars alike—and they’re meant to support, not replace, good mirror checks and head turns.

Top safety benefits from BSM:

- Fewer lane-change collisions: better detection of vehicles in adjacent lanes reduces misjudged maneuvers.

- Faster reaction times: instant visual or haptic cues shorten driver response in critical moments.

- Lower injury risk: earlier warnings help avoid collisions or reduce impact severity.

Because of these benefits, correct repair and recalibration after collisions are essential to restore system accuracy and maintain driver trust. Prime Time Collision Center provides OEM-quality ADAS and BSM repair and calibration, performed by certified technicians following manufacturer procedures to return systems to spec.

What Are the Common Problems That Affect Blind Spot Monitoring Systems and When Is Repair Needed?

BSM systems most often fail because sensors or their mounts are physically damaged, sensors are blocked, wiring or connectors are compromised, or software states change after repairs. Symptoms point to the likely cause: a constant BSM warning light, phantom alerts, no alerts when another vehicle is present, or reduced range after bumper or suspension work. Simple issues—like dirt on a sensor—may clear with cleaning and a reset, but crashes that alter bumper structure, sensor housings or wiring usually need a professional inspection, diagnostic scan and possible sensor replacement followed by calibration.

| Symptom | Likely Cause | DIY Check | When to Call a Shop |

|---|---|---|---|

| No alerts at all | Faulty sensor or control module; disconnected wiring | Check dashboard warnings and visually inspect sensors | If the warning persists or connectors look damaged |

| False/phantom alerts | Misaligned sensor or calibration drift | Clean the sensor and test at low speed | If alerts continue after cleaning |

| Persistent BSM warning light | Stored diagnostic trouble codes or sensor faults | Cycle the ignition to see if the light clears | When the light stays on or returns |

| Decreased detection range | Sensor obstruction or misalignment | Remove debris and check bumper fitment | If bumper is damaged or sensor housing cracked |

What Causes Blind Spot Monitor Malfunctions After Collisions?

After an impact, BSM problems often stem from direct hits to sensors, shifted sensor mounts, deformed bumper assemblies or damaged electrical connectors. Even small impacts can change the precise angle of radar or camera sensors and shift detection cones outside manufacturer tolerances, producing missed detections or false alarms. Wiring routed through bumper areas can be pinched or disconnected during a collision or tow, creating intermittent faults and warning lights. Because these issues change the geometry and reference points the control module depends on, professional inspection and calibration are commonly necessary to restore correct operation.

How Can Drivers Troubleshoot Common Blind Spot Monitor Issues?

You can perform a few safe, first-step checks to rule out easy fixes before scheduling a repair. Focus on sensor cleanliness, bumper fitment and any warning messages. Start by wiping visible sensor faces with a soft cloth and mild cleaner, then look for gaps or shifted trim that could misalign sensors. Restart the vehicle and watch whether the warning lamp clears. Note when faults occur—speed, weather or road conditions—and check the owner’s manual for reset steps. If problems continue or the issue followed a collision, contact a certified repair center for a diagnostic scan and calibration rather than attempting invasive repairs yourself.

Simple checks drivers can try:

- Clean visible sensor lenses to remove dirt, ice or salt.

- Ensure bumper panels and sensor mounts sit flush after minor impacts.

- Restart the vehicle and watch the BSM warning indicator.

- Log when faults happen to help the technician diagnose the issue.

How Does Expert Blind Spot Monitor Repair and Sensor Replacement Work?

Professional BSM repair follows an OEM-focused workflow: diagnostic scan and physical inspection, controlled sensor replacement if needed, then ADAS calibration and validation. Technicians start by reading diagnostic trouble codes from the BSM module and testing sensor outputs to pinpoint hardware or electrical faults. A hands-on inspection checks bumper damage, sensor housings and connector condition. When parts must be replaced, OEM-grade sensors are preferred to preserve factory specs and electrical compatibility. After mechanical work, technicians perform static and dynamic calibration to realign sensors to manufacturer reference points, then validate operation with verification tests and a road test.

Typical repair workflow:

- Diagnostic scan and physical inspection to find the fault.

- Order and install OEM or matched replacement parts as required.

- Perform static and dynamic ADAS calibration per manufacturer procedures.

- Validate system operation with verification tests and a test drive.

Below is a repair table clarifying typical tasks and calibration needs.

| Repair Phase | Typical Tasks | Time / Complexity | Requires Calibration |

|---|---|---|---|

| Diagnosis | Scan the control module, inspect sensors and wiring | 0.5–1 hour, low complexity | No (initial) |

| Sensor Replacement | Remove bumper cover and replace the sensor module | 1–2 hours, moderate complexity | Yes |

| Wiring Repair | Repair or replace connectors and harness sections | 1–2 hours, variable | Sometimes |

| ADAS Calibration | Set up static targets and perform dynamic validation | 0.5–2 hours, requires specialized equipment | Yes |

What Is the OEM Certified Repair Process for Blind Spot Monitoring Systems?

OEM-certified repairs follow the manufacturer service manual and documented calibration steps from start to finish: accurate damage appraisal, OEM diagnostics, correct part installation, and validated system performance. Certified technicians follow repairability guidelines, use factory diagnostic tools to read and clear codes, and follow step-by-step instructions when replacing sensors or adjusting mounts so structural and electronic integrity is preserved. Detailed documentation is kept for insurance and safety records, and a post-repair verification routine confirms visual indicators, audible alerts and haptic feedback work within manufacturer tolerances. This disciplined approach reduces residual faults and helps return the vehicle’s safety systems to factory intent.

Why Is Using Certified Technicians and OEM Parts Critical for BSM Repairs?

Certified technicians and OEM parts matter because sensor orientation, signal behavior and software compatibility are tightly controlled by manufacturers. Deviations can reduce detection accuracy and may void warranties. Certified techs hold credentials—such as I-CAR or manufacturer certifications—and use factory-level diagnostic tools and calibration equipment for precise alignment. OEM parts ensure proper fit, sealing and electrical compatibility; aftermarket pieces that don’t meet factory tolerances can create detection gaps or change system thresholds. Choosing certified repairs protects system performance and preserves the documentation insurers and future owners rely on.

Why Is Blind Spot Monitor Calibration Essential After Repairs or Accidents?

Calibration restores the geometric and software reference points sensors use to accurately detect and classify nearby vehicles. Without calibration, even correctly installed sensors can deliver misleading data and undermine safety. Calibration realigns sensor aim, updates control module reference values and verifies detection zones through static and dynamic testing to ensure sensors meet manufacturer tolerances. For safety-critical features like BSM, minor misalignment can create false negatives (no warning when a vehicle is present) or false positives that erode driver trust. For that reason, calibration is recommended or required after sensor replacement, bumper repairs, frame straightening or suspension and alignment work.

Calibration provides these outcomes:

- Correct detection geometry: Sensors report accurate angles and ranges after alignment.

- Consistent performance: System behavior becomes repeatable across conditions.

- Verified safety: Static and dynamic tests confirm real-world effectiveness after repair.

How Does Calibration Ensure Accurate Functionality and Safety of BSM Systems?

Calibration sets precise sensor orientation and control-module reference values so the system interprets object position and velocity correctly and warns only when appropriate. Typical procedures include placing calibration targets at defined distances and angles for cameras and radar, running factory diagnostic routines to store reference points, and performing dynamic validation drives to confirm detection in normal traffic. Combining static target alignment with real-world testing shows whether the system meets manufacturer thresholds for detection and alert timing. Proper calibration turns correct hardware installation into reliable, standards-compliant safety performance.

What Specialized Equipment and Procedures Are Used for ADAS Calibration?

ADAS calibration uses tools such as optical target rigs, radar test benches, OEM diagnostic scan tools and alignment fixtures to recreate factory reference conditions for sensors. Camera systems require calibrated targets at specific distances and heights; radar modules may need test benches or measured field setups to verify beam patterns and range. Diagnostic software interfaces with vehicle control modules to run calibration sequences, log reference values and confirm success. Because tools and procedures vary by manufacturer, certified shops keep multiple toolsets and OEM software subscriptions to handle a wide range of vehicles safely and accurately.

How Does Prime Time Collision Center Support Insurance Claims and Customer Trust for BSM Repairs?

Prime Time Collision Center helps with insurance claims and builds customer confidence by documenting OEM repair needs, coordinating with major insurers, and delivering certified ADAS and BSM repairs that prioritize safety and factory procedures. Our shop employs I-CAR Platinum and Honda Certified technicians who follow manufacturer repair manuals and use calibrated equipment for sensor replacement and ADAS calibration—details that help justify OEM parts and calibration to adjusters. We provide free estimates, assist with documentation for claims, and back repairs with warranties; we also offer towing and mechanical accident repairs so safety systems are addressed comprehensively. By combining thorough damage appraisals with OEM-aligned repair workflows, we help ensure insurers understand why parts and calibration are necessary for safe vehicle operation.

How we support customers:

- Clear, documented estimates that specify OEM part needs and calibration steps.

- Coordination with major insurance companies to help get ADAS/BSM repairs approved.

- Free estimates and towing to simplify post-accident logistics.

How Does Prime Time Collision Assist with Insurance for ADAS and BSM Repairs?

We produce OEM-based estimates and repair plans that explain sensor replacement and calibration needs for adjuster review. Our technicians supply diagnostic reports, photos of damaged components and documentation of required ADAS calibration procedures to create a transparent case for insurer approval. Our experience working with major insurers helps speed communication and claim processing, increasing the chance that OEM parts and calibration services are authorized. That coordination reduces repair delays that could otherwise leave safety systems degraded.

What Certifications and Guarantees Build Trust in Prime Time Collision’s BSM Services?

Certifications like I-CAR Platinum and Honda Certified show our technicians have manufacturer-specific training and the technical skills required for OEM-compliant repairs and calibrations. Those credentials, together with satisfaction guarantees and repair warranties, give customers documented assurance that work follows factory procedures and that systems will perform as intended after the repair. Coupled with free estimates and 24/7 towing availability, these credentials help vehicle owners choose a provider focused on OEM-quality repairs and full ADAS restoration—not quick fixes that could compromise safety.

If you’re ready to restore your vehicle’s safety systems after a collision or want to verify BSM performance, Prime Time Collision Center offers free estimates and insurance coordination. Our certified technicians and warranty-backed repairs prioritize OEM-quality results so your ADAS and blind spot monitoring systems perform as intended. Contact us locally to schedule an inspection, diagnostic scan and certified calibration.

Frequently Asked Questions

What should I do if my blind spot monitoring system is malfunctioning?

Start with simple checks: look for dirt, ice or debris on sensor faces and gently clean them. Inspect the bumper and sensor mounts for visible damage or misalignment. If the issue remains, visit a certified repair facility for a diagnostic scan—technicians can read fault codes, test sensors and restore proper calibration.

How often should blind spot monitoring systems be calibrated?

Calibrate whenever sensors, bumpers or any components that affect sensor alignment are repaired or replaced. Calibration is also recommended after significant impacts or collision repairs—even if the sensors look undamaged. Regular checks during routine maintenance help keep the system accurate.

Can I perform repairs on my blind spot monitoring system myself?

You can try basic troubleshooting—cleaning sensors, checking for visible damage or restarting the vehicle. But most repairs and calibrations require specialized tools and training, so certified technicians should handle sensor replacement, wiring repairs and ADAS calibration to avoid safety risks.

What are the signs that my blind spot monitoring system needs repair?

Look for persistent warning lights, false alerts, no alerts when another vehicle is present, or reduced detection range. Any of these signs indicate you should get a professional inspection and possibly a diagnostic scan and calibration.

How does weather affect the performance of blind spot monitoring systems?

Weather can impact radar and camera sensors—heavy rain, snow or fog may reduce effectiveness and cause missed detections or false alerts. Ice or snow on sensor surfaces will block them. Regular cleaning and avoiding driving with obscured sensors help maintain reliability.

What is the difference between static and dynamic calibration for blind spot monitoring systems?

Static calibration uses fixed targets placed at specific distances and angles to align sensors to factory specifications. Dynamic calibration tests the system while the vehicle is in motion to verify detection in real-world conditions. Both steps are important to ensure the system works correctly and safely.

How can I ensure my blind spot monitoring system is functioning correctly after a repair?

Ask the shop for a full diagnostic scan and both static and dynamic calibration. Technicians should validate the system with verification tests and a road test. After the repair, monitor the system during your first drives and report any persistent warning lights or inconsistent alerts to the repair facility.

Conclusion

Blind spot monitoring systems are a proven safety aid that reduce lane-change collisions and improve driver awareness. To keep those benefits, proper repair and calibration after any impact are essential. For OEM-quality ADAS and BSM repairs, Prime Time Collision Center offers certified technicians, documented estimates and warranty-backed work to restore your vehicle’s systems to factory standards. Reach out to us today for an inspection and free estimate.