Keep Your Headlights Clear: Professional Restoration & UV Protection That Lasts

When the polycarbonate lens or its factory clear coat breaks down, headlights turn cloudy, yellow, or pitted. That haze cuts light output and makes night driving less safe. Left unchecked, minor scratches and UV damage lead to poorer beam focus and more glare for everyone on the road.

This guide breaks down why headlights yellow, how professional restoration recovers lumen output and realigns the beam, and which preventative options—UV coatings, paint protection film (PPF), and safe maintenance—actually extend clarity. You’ll get a step‑by‑step look at restoration, objective safety benefits, and practical tips for drivers in sunny regions. We also explain how headlight care fits into collision repair workflows and where certified shops like Prime Time Collision Center add value for drivers in Glendale and surrounding communities.

What Causes Headlight Haze and Oxidation?

Headlight haze happens when the lens loses optical clarity. The main drivers are UV‑driven photo‑oxidation of the lens or clear coat, mechanical abrasion from road debris, and chemical attacks from harsh cleaners or road salts. The result is scattered light, lower lumen transmission, and a blurred beam that increases glare and shortens effective stopping distance. Knowing the causes helps you choose the right prevention: block UV, avoid abrasive cleaners, and address small scratches before they grow. Quick reference:

- UV radiation: Long sun exposure breaks polymer bonds and degrades clear coats, producing yellowing and micro‑cracks.

- Mechanical abrasion: Sand, grit, and road debris create micro‑scratches that scatter light and speed clear coat loss.

- Chemical exposure: Harsh cleaners, salts, and pollutants weaken the surface polymers and accelerate clouding.

- Moisture intrusion: Condensation inside the housing can corrode reflectors and add internal fog that worsens oxidation.

With those causes in mind, targeted fixes—UV barriers and careful polishing—are much more effective than one‑off DIY attempts.

How Does UV Radiation Affect Polycarbonate Headlight Lenses?

UV light starts a chemical chain reaction in polycarbonate and the thin clear coat that protects it. Over months or years in strong sun, polymer chains break down, the surface roughens, and tiny cracks or yellowing appear. That change scatters light and reduces measured lumen output. A lens that once produced a crisp cutoff will begin to diffuse light, creating more glare and noticeably reducing effective illumination distance. Studies show UV damage is often the fastest early‑stage clarity loss, which is why UV protection is a top prevention priority in sun‑heavy areas.

Next we’ll look at how professional restoration reverses these effects and what visibility gains you can expect.

How Can Professional Headlight Restoration Improve Visibility and Safety?

Professional restoration removes the oxidized layer, restores lens geometry, and finishes the surface with a durable UV seal. The result is stronger lumen output, a tighter beam pattern, and less glare—usually at a fraction of the cost of full replacement. Trained technicians follow calibrated processes that preserve optical shape and meet alignment and inspection standards, which directly improves nighttime stopping distance and driver confidence.

Here’s a quick comparison of restoration versus replacement so you can weigh cost, downtime, and outcome.

| Service Option | Typical Outcome | Practical Impact |

|---|---|---|

| Professional Restoration | Recovers clarity and beam pattern; finished with a UV protective coating | Better night visibility, lower cost, less time without your vehicle |

| Full OEM Replacement | New lens with factory coatings and exact fit | Top optical performance, higher parts cost, longer lead time |

| Temporary DIY Polishing | Short‑lived improvement without professional sealing | Clouding returns sooner; risk of over‑sanding or uneven finish |

For lenses with surface oxidation, restoration often gives the best safety‑for‑cost result. Replace when the housing, internal components, or lens geometry are compromised.

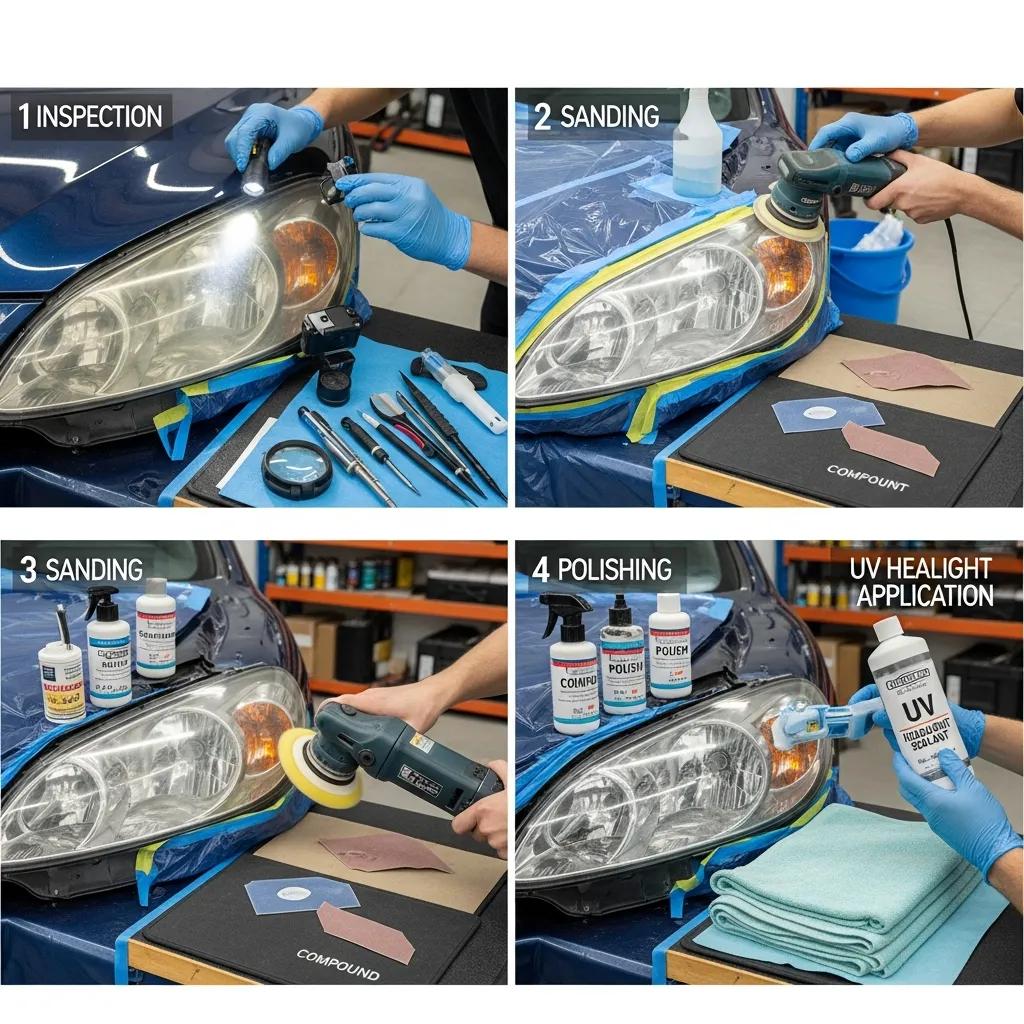

What Is the Step‑by‑Step Process of Professional Headlight Restoration?

A typical professional restoration follows a controlled workflow: inspect and document lens condition, mask paint and trim, wet‑sand in staged grits to remove oxidized clear coat, polish with successively finer abrasives to recover gloss, then apply a hard UV‑resistant sealant or ceramic layer and verify optical alignment. The inspection also checks for internal moisture and reflector damage to decide restore‑versus‑replace. Proper grit progression removes surface damage without changing lens curvature, and the final seal restores UV resistance and longevity. Most full restorations finish in a single session, though coating cure times vary by product.

Why Choose I‑CAR Platinum Certified Technicians for Headlight Care?

I‑CAR Platinum means technicians have advanced training across structural, electrical, and refinish areas important to collision and optical repairs. Certified teams follow manufacturer repair procedures, which lowers the chance of misaligned optics or material mismatches that can affect safety systems. After a collision, certification also gives insurers confidence and helps ensure repairs meet warranty and claims requirements. In short, certified technicians tie headlight quality to broader vehicle safety and repair traceability.

With those benefits in mind, local trust signals and service options become important when you pick a shop for restoration and protection.

Prime Time Collision Center combines professional restoration techniques with certified quality controls and customer services built for local drivers. As a Glendale‑area auto body and collision shop focused on OEM‑quality repairs and insurance work, we offer free estimates, insurance coordination, and a lifetime warranty on covered repairs. We also provide 24/7 towing for customers after accidents. That mix of technical process and customer support complements the restoration steps above while keeping safety front and center.

What Are Effective Methods for Preventing Headlight Oxidation?

Preventing oxidation works best when you combine protective products with sensible habits: apply a professional UV sealant or ceramic coating, consider paint protection film (PPF) as a sacrificial barrier, and keep to safe cleaning routines that avoid abrasives. These options vary in cost, longevity, and repairability, but they all reduce the main culprits—UV and mechanical wear. A layered approach—PPF backed by periodic sealant maintenance—gives the longest practical protection in high‑sun areas. Quick guide:

- Professional UV sealants / ceramic coatings: chemically block UV and add a hard, water‑shedding surface for years.

- Paint Protection Film (PPF): a replaceable transparent layer that absorbs chips and abrasion.

- Safe cleaning and waxing: use non‑abrasive detergents and reapply protectant as recommended.

- Behavioral changes: park in shade, use covers, and reduce direct sun exposure when possible.

Below is a simple longevity comparison to help you choose the right protection strategy.

| Protection Method | Characteristic | Typical Longevity |

|---|---|---|

| UV Sealant / Ceramic Coating | Chemical UV barrier with a hard finish | 1–3 years depending on product and care |

| Paint Protection Film (PPF) | Physical sacrificial barrier | 3–7 years with professional maintenance |

| Regular Waxing / Sealant | Surface hydrophobic protection | 3–6 months without professional recoat |

| Simple Cleaning | Removes contaminants but offers no UV block | Immediate clarity; no long‑term protection |

Choose based on how long you need protection, whether you prefer a repairable film, and your budget for upkeep.

How Do UV Protective Coatings and Paint Protection Film Work?

UV coatings contain molecules that absorb or reflect UVA/UVB energy to stop photo‑oxidation. Ceramic variants chemically crosslink into a hard layer that resists scratches and staining. PPF is a clear polymer film applied to the lens that sacrificially takes rock chips and abrasion while keeping the original lens underneath. Coatings are sprayed or painted and cure chemically; PPF is precision‑cut and installed to the lens shape. Both need proper surface prep to adhere correctly. Many drivers get the best results by combining PPF with a ceramic top coat for longer protection.

Coatings are re‑applied over time; PPF sections can be replaced locally if damaged without disturbing the lens.

What DIY Tips Help Maintain Headlight Clarity?

DIY care helps when done safely: use pH‑neutral automotive soap, microfiber towels, and non‑abrasive cleaners. Avoid household abrasives like toothpaste for long‑term care. Inspect headlights regularly for small scratches and contaminants, and schedule professional restoration before damage reaches the clear coat. Parking in shade or using covers cuts cumulative UV exposure. Know when to stop DIY—deep yellowing, internal condensation, or housing damage are best handled by pros to protect optics and safety.

These everyday steps complement periodic professional protection and keep clarity longer.

How Does Headlight Restoration Integrate with Collision Repair Services?

Headlight care is part of the collision repair workflow: it starts at damage assessment, feeds into insurance documentation, and follows a restore‑versus‑replace decision tree based on safety, geometry, and cost. After an accident, technicians evaluate lens integrity, internal component condition, and alignment needs to determine whether restoration will safely restore performance or if OEM replacement is required. Good documentation supports claims and ensures compatibility with other systems like leveling sensors and camera calibrations. Process mapping clarifies who handles each step and why certification matters.

| Service Step | Who Performs | Certification / Benefit |

|---|---|---|

| Initial Inspection & Documentation | Certified estimator/technician | Supports insurance claims; identifies OEM needs |

| Restore vs Replace Decision | Lead technician with repair standard | Ensures safety and optical performance |

| Optical Alignment & Calibration | Trained technician (electrical/diagnostic) | Preserves beam pattern and safety systems |

Clear roles and certified processes lower insurer disputes and keep repairs focused on safety.

Why Are OEM Certified Headlight Repairs Important After an Accident?

OEM‑certified repairs use manufacturer‑specified parts and procedures that preserve performance, calibration, and system compatibility—especially when headlights tie into adaptive lighting, sensors, or vehicle electronics. OEM parts reduce fitment issues, ensure correct beam cutoffs, and meet many insurers’ and warranties’ expectations. For leased or high‑value vehicles, OEM repairs help protect resale value with documented, factory‑spec work. In short, OEM adherence reduces the chance of post‑repair problems from mismatched aftermarket parts.

This OEM focus supports smoother insurer interactions and clearer documentation for customers.

How Does Insurance Claim Assistance Simplify Headlight Repair?

Insurance claim assistance reduces hassle by preparing estimates, photographing damage, and coordinating directly with adjusters to justify restoration or replacement decisions. A shop that manages these steps provides itemized estimates, documents pre‑ and post‑repair condition, and communicates timelines so you know what to expect. Direct billing or claims help speeds approvals and vehicle return while lowering out‑of‑pocket surprises. Good documentation also simplifies warranty follow‑ups or recalibrations after repair.

These services are especially helpful when multiple systems need coordinated attention after a collision.

Prime Time Collision Center offers integrated claims support alongside OEM‑quality repairs. We work with all major insurers to streamline approvals and we provide free estimates, 24/7 towing, and a lifetime warranty on qualifying repairs—services designed to reduce stress and ensure headlights and related systems meet OEM expectations.

What Are the Benefits of Choosing Prime Time Collision Center for Headlight Care?

Picking a local, certified shop gives real advantages: trained technicians who follow OEM procedures, bundled services that simplify insurance work, and warranties that reduce long‑term risk. Prime Time Collision Center highlights I‑CAR Platinum certified technicians and a lifetime warranty on covered repairs—features that support consistent results and peace of mind for drivers concerned about visibility and resale value. Free estimates and around‑the‑clock towing keep logistics simple after an accident or for scheduled service. We serve Glendale, Burbank, Pasadena, and Los Angeles, so help is nearby for many commuters. Key benefits:

- Certified Expertise: Trained technicians deliver consistent restoration and correct optical alignment.

- Warranty Protection: A lifetime warranty reduces long‑term risk from workmanship or materials.

- Claims and Logistics: Free estimates, insurance coordination, and towing simplify the repair journey.

These services lower friction and support the technical protection strategies described earlier, making it easier to keep your headlights safe and clear.

How Does a Lifetime Warranty Enhance Trust in Headlight Restoration?

A lifetime warranty shifts risk from you to the provider by covering workmanship or material defects for the covered period. That backing gives confidence in restoration durability and helps with lease returns or resale—documented repairs are easier to explain to insurers or buyers. Warranty claims usually need proof of service and may include follow‑up inspections, which encourages proper maintenance instead of risky DIY fixes. For something as safety‑linked as headlight clarity, a warranty is meaningful protection.

Knowing what the warranty covers and how to claim it helps you feel secure about long‑term costs and performance.

What Do Customers Say About Our Headlight Haze Removal Service?

Customers consistently praise improved night visibility, reduced glare, and a smooth repair experience that includes clear insurance help. Common notes mention restored long‑range illumination, straightforward communication during claims, and the convenience of bundled services like towing and free estimates. Before‑and‑after photos are often the most persuasive evidence—showing real, measurable improvement in lens clarity and beam focus.

Those recurring themes explain why professional restoration plus preventive coatings and a clear warranty deliver the best long‑term outcome for drivers.

If you drive in the Glendale area and need headlight restoration or collision repair, schedule a free estimate to assess lens condition and protection options. Prime Time Collision Center can handle the inspection, insurance documentation, and recommended protection to keep your headlights performing safely for years.

Frequently Asked Questions

What are the signs that my headlights need restoration?

Look for yellowing, cloudiness, or a dull, faded lens surface. If your headlights aren’t lighting the road as well at night, or if oncoming drivers flash at you because of glare, that’s a clear sign. Internal condensation or moisture also indicates issues that likely need professional attention. Regular checks catch problems early.

How often should I have my headlights professionally restored?

Frequency depends on sun exposure and driving conditions. For many drivers, restoration every 1–3 years is a good rule of thumb—sooner in very sunny or harsh environments. Professional UV sealants or ceramic coatings can lengthen the interval between full restorations.

Can I perform headlight restoration myself, and is it effective?

DIY kits can give short‑term improvements, but they usually don’t match professional durability. DIY sanding and polishing risks uneven results or over‑sanding. Professionals preserve lens geometry and apply a proper UV seal, so for severe oxidation or when longevity matters, we recommend a pro service.

What should I look for in a headlight restoration service?

Choose experienced, certified technicians who document the process and use high‑quality materials like UV sealants or ceramic coatings. Read reviews, ask about their restoration steps, and prefer shops that offer warranties—those things indicate consistent results and accountability.

Are there any risks associated with headlight restoration?

Restoration is safe when done correctly, but improper sanding or poor materials can distort the lens or shorten the outcome’s lifespan. That’s why trained technicians and quality coatings matter. Regular maintenance after restoration also helps prolong clarity and avoid repeat problems.

How do I maintain my headlights after restoration?

Clean regularly with pH‑neutral automotive soap and a microfiber cloth. Avoid abrasive household cleaners. Reapply a UV sealant or have a ceramic recoating as recommended by your service provider. Park in shade when possible and inspect headlights periodically for chips or clouding so you catch issues early.

Conclusion

Clear, correctly functioning headlights matter for safety—especially in sunny regions where oxidation progresses fast. Professional restoration combined with the right preventive measures can restore visibility and extend lens life. Prime Time Collision Center offers expert restoration, protective options, and the local support to make it simple: free estimates, insurance assistance, 24/7 towing, and a lifetime warranty on qualifying repairs. Schedule a free estimate today and let us help keep your headlights bright and your drives safer.